Houston’s Premier Metal Roofing Contractor

for

Houston Metal Roofing Systems

and Standing Seam Metal Roofing

//////////

The first choice in Houston for Metal Roofs, Aluminum Roofing, Aluminum Shake & Shingle and Standing Seam Roofs, All Star Roof Systems, Inc. has been Houston’s premier metal roofing contractor for almost 50 years. All Star Roof Systems is best known for the installation of high quality aluminum shake & shingle roofs and standing seam metal roofs. Our sales staff has extensive experience in dealing with all insurance companies, and all of our roof installers are certified with a minimum of 20 years experience.

In addition to being the best at providing Aluminum Roofing, Aluminum Shake & Shingle Roofs, and Standing Seam Metal Roofs, All Star Roof Systems, Inc. is a leader in other types of roofs including composition roofs and TPO roofs. We are endorsed as the roofers of choice in Houston by Todd Miller, President of Classic Metal Roofing Systems. We know the right products and have the experience and expertise to handle your project better than any of the other Houston roofing contractors.

If you would like to read some of the reviews and testimonials some of our clients have sent us, please take a moment to see our testimonials page. We also encourage you to take a few minutes to browse our roofing galleries and see examples of our work in the area. We have a gallery for aluminum shake and shingle homes, a gallery for standing seam roofing projects, and a gallery for composition roof homes. We are also pleased to present Metal Roofing 101 by Todd Miller, President Classic Metal Roofing Systems. In these videos, Todd shares valuable information and experience about metal roofing systems. If you would like a free roof estimate or if you have any questions, please contact us.

Best Prices

All Star Roof Systems offers the best quality products and workmanship at the best prices in the greater Houston area. Call today and let us provide you with a free estimate.

Best Contractor

All Star Roof Systems is a top tier contractor that is dependable and consistently delivers quality on-time installation of metal roofing products.

Well Established

All Star Roof Systems, Inc. has been Houston’s premier metal roofing contractor for almost 50 years.

Best Craftsmen

All Star Roof Systems maintains an experienced staff of craftsmen known for their quality work and on-time performance.

Why Choose Metal Roofs?

//////////

Metal roofs are used on many kinds of buildings such as apartment complexes, fire stations, churches and your neighborhood three-bedroom home. Metal roofs provide beauty, energy savings, and lifetime protection for your home. Residential metal roofs are available in a wide variety of colors to complement any style home or building. Available in many colors, All Star Roof Systems provides traditional standing seam steel roofs as well as aluminum shake and shingle roofing manufactured to resemble wood shake, slate, or shingles.

Let All Star Roof Systems share some insight into metal roof cost. We can show you that while they may cost more than composite roofs to install, it is actually much less expensive over the life of you home and can save you a lot of money in the long run. While your neighbors may re-roof their home many times, a high-quality metal roof will likely be the last roof you’ll ever need.

By choosing a metal roof, you’ll both save money and benefit the environment. Conventional asphalt composition roofing products contribute an estimated 20 billion pounds of waste to landfills in the USA annually. This can be avoided when you go with a metal roof since they can often be installed over an existing roof. This saves cost and avoids the environmental impact of disposal. One of the best benefits is that all metal roofs are made from 30-60% recycled material.

Many residential metal roofs now utilize reflective coatings technology which provides for home energy efficiency and lower utility bills.

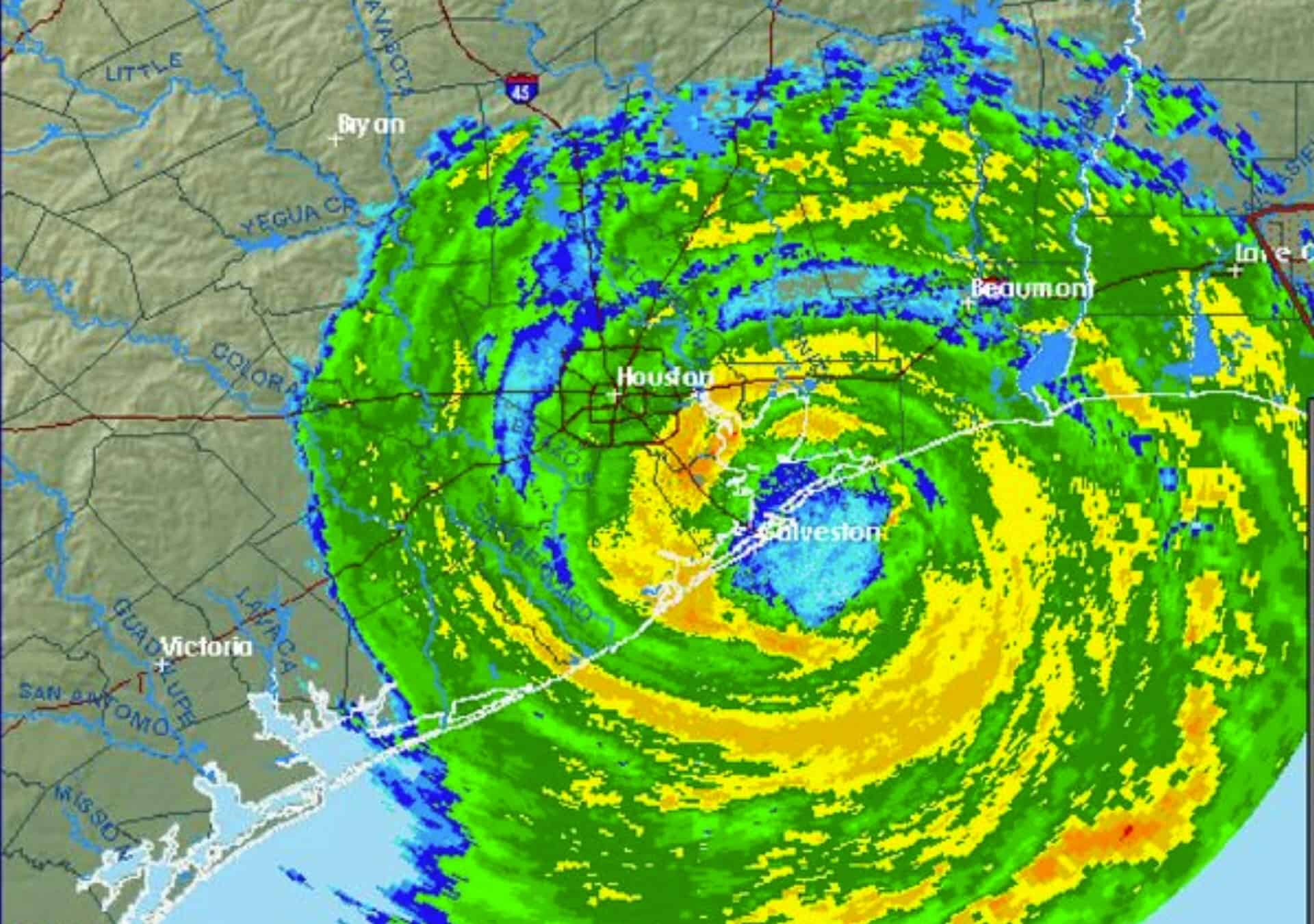

Metal roofs are resistant to cracking, shrinking, and erosion. They can also withstand extreme weather conditions and wildfires better than any other roofing material.

ALUMINUM SHAKE

Classic Metal Roofing Systems has named All Star Roof Systems, Inc. as the exclusive authorized dealer of the Country Manor Aluminum Shake product in the Houston area.

STEEL SHINGLE

This beautiful roofing is made in America and designed to fit in with the look of your home while enhancing the integrity and weather-hardiness of your house for decades to come.

STANDING SEAM

All Star Roof Systems provides steel standing seam metal roof systems with expected lives of approximately 40 years. We’ve even enhanced our performance and testing to ensure our products can meet the demands of hurricane force winds.

COMPOSITION SHINGLE

All Star Roof Systems offers composite roof systems by GAF Roofing, CertainTeed Roofing and Owens Corning Roofing.

Houston Metal Roofing Systems

Aluminum Shake & Shingle Roofing

Standing Seam Metal Roofing

Composition Roofing – TPO Roofing

//////////

We are proud of our work as one of the leading commercial and residential metal roofing contractors in Spring. Serving the greater Houston area, our commitment is simple: setting new standards of quality, integrity, customer service, expertise and value. We specialize in Aluminum Shake & Shingle Roofs and Standing Seam Metal Roofs.

We provide Turnkey Roofing Solutions to custom home builders using the highest quality materials available in the industry at a competitive price. Our metal roof installation crews have extensive experience in new construction roofing and decking. We work directly with custom home builders, homeowners, and contractors for single construction projects and have the capabilities to manage the requirements for developers building multiple properties.

Let our experienced and certified metal roofing contractors come out and inspect your roof free of charge. It is always a good time to have your roof and gutters inspected. The sun along with rain, hail, and strong winds can loosen shingles and expose your roof. All Star Roof Systems is the Houston roofing company that will get the job done right.